Can You Bend RFID Tags? A Guide to Types, Printing, and Encoding of Flexible RFID Tags

2023-12-28 17:28

In today’s world, RFID (Radio-Frequency Identification) tags have become integral in asset tracking and inventory management. In practical applications, you’ll notice that many RFID tags are capable of bending, such as RFID clothing tags and medical device RFID tags. These tags are known as Flexible RFID Tags. In this article, we’re going to explore these fascinating tags through several selected questions, delving into their types, characteristics, and how to print and encode them.

Can You Bend RFID Tags? Is RFID Flexible?

Traditionally, these RFID tags were rigid, limiting their application to flat, non-flexible surfaces. However, the advent of flexible RFID tags has revolutionized the industry.

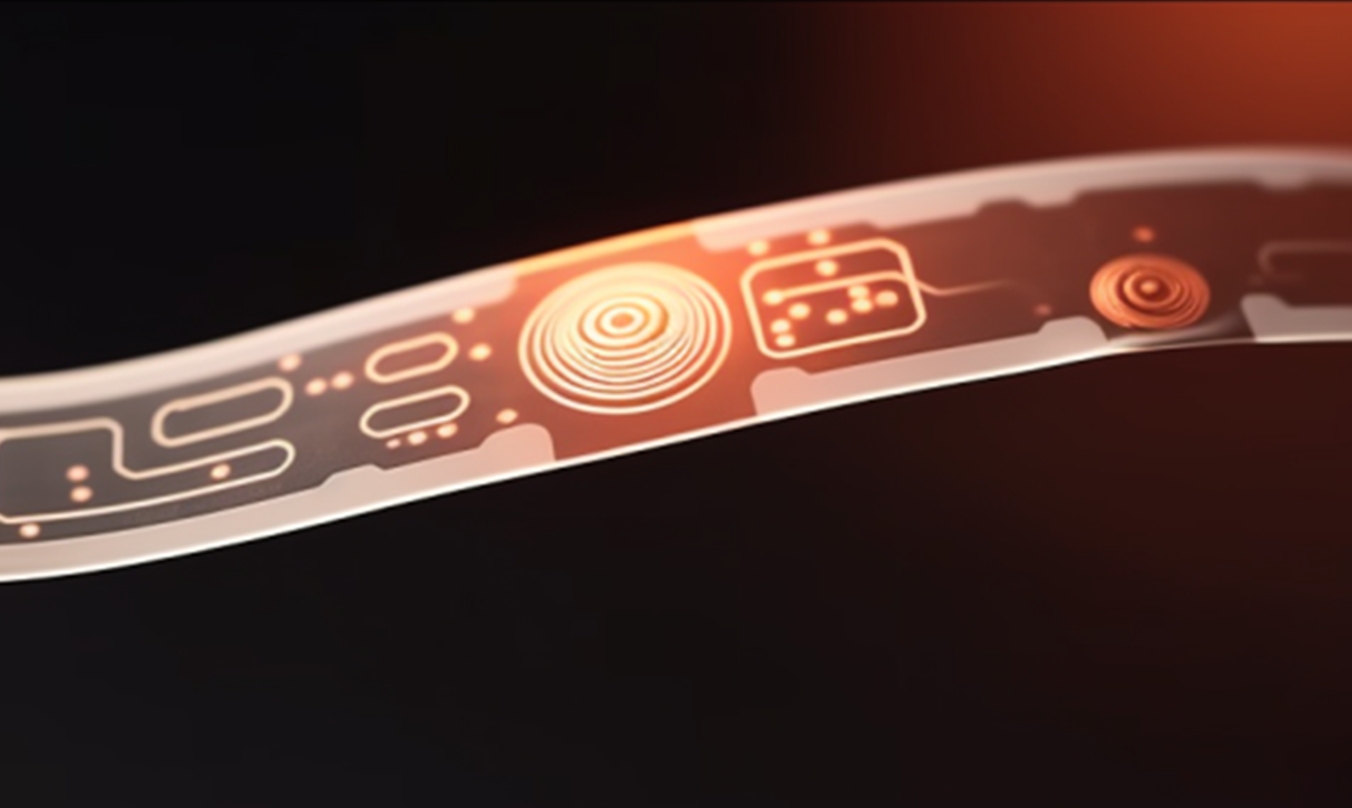

These soft RFID tags, made from materials like special plastics, paper or fabrics, are suitable for curved surfaces or applications requiring a certain level of flexibility. In the retail sector, for example, RFID clothing tags blend seamlessly into garments, enhancing inventory management without impacting design or comfort.

The flexibility of an RFID tag also depends on the design of its internal antenna. Advanced antenna designs enable these tags to maintain functionality when bent or twisted. Their ability to function on curved surfaces and in different conditions makes them a valuable tool in modern RFID applications.

What Are the Types of Flexible RFID Tags?

Flexible RFID tags can be categorized into Low Frequency (LF), High Frequency (HF), and Ultra-High Frequency (UHF) types, each suited for specific applications.

1. Low Frequency (LF) RFID Tags

LF tags, typically operating around 125 kHz, are ideal for short-range uses like access control and animal identification, offering minimal interference from metals and liquids.

2. High Frequency (HF) RFID Tags

HF tags, operating at 13.56 MHz, are perfect for moderate-range applications such as library book tracking and contactless payments.

3. Ultra-High Frequency (UHF) RFID Tags

UHF flexible RFID tags, in the 860-960 MHz range, excel in logistics, and supply chain management due to their long read ranges, making them ideal for asset tracking and inventory management in large-scale environments.

The application of flexible RFID labels spans a wide array of industries, including apparel and textile, healthcare, retail, logistics and supply chain, as well as automotive and electronics.

For instance, soft RFID tags prove particularly useful when attached to soft medical items, such as bandages or flexible containers, enhancing the efficiency and safety of patient care.

In the automotive and electronics industries, a specialized type of soft RFID tag known as a flexible anti-metal tags is increasingly being utilized. These tags’ unique antenna designs allow them to adhere to and function on metal surfaces like car engines and electronic device casings, overcoming traditional RFID limitations.

The RFID PCB Tags are particularly notable in this category for their strong resistance to collision and corrosion. They are widely used in asset management fields such as shelf identification and warehouse asset management due to these characteristics.

Can Flexible RFID Tags Be Written? Can RFID Tags Be Printed?

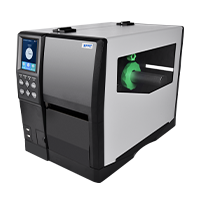

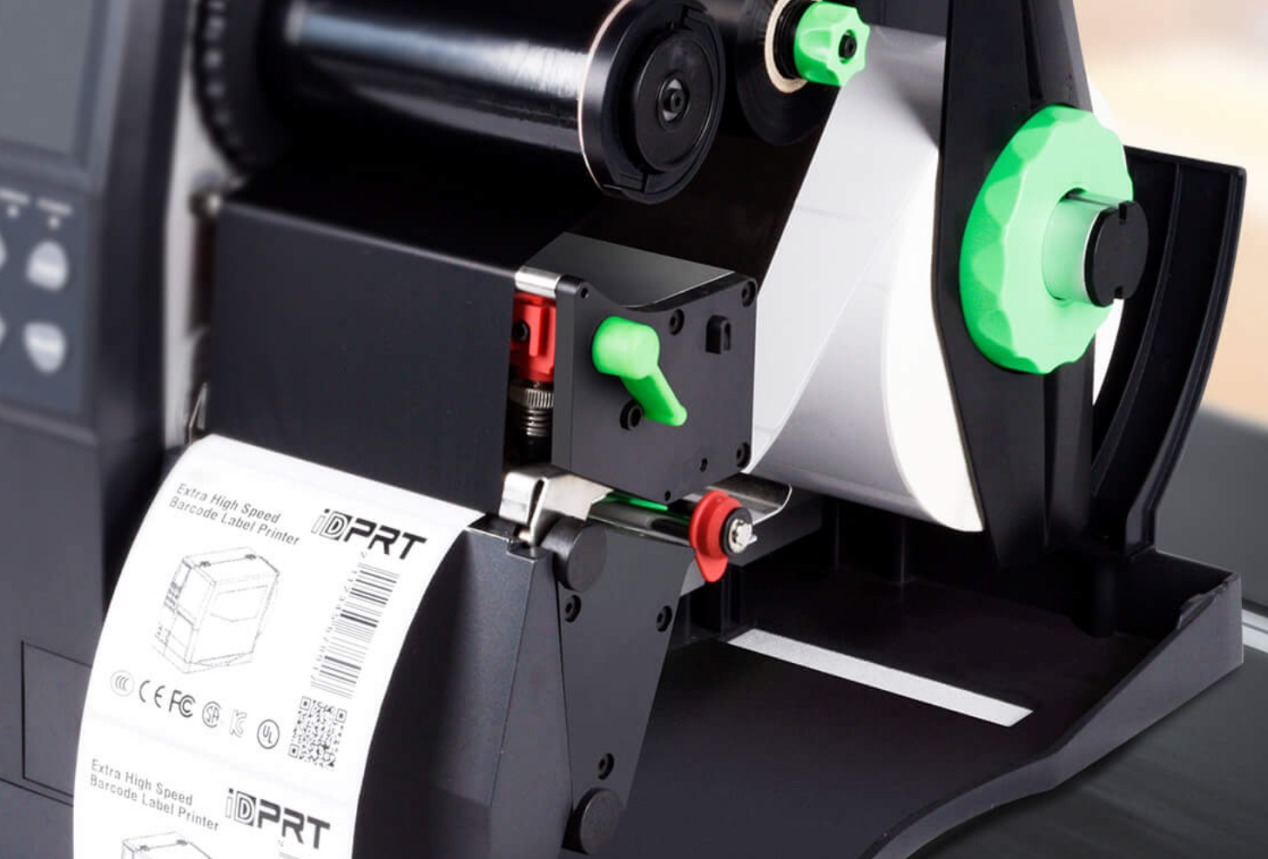

One of the most significant advancements in RFID technology is the capability to write on and print these RFID tags and labels, allowing for the customization of tags with specific data. Flexible RFID labels are no exception. This process can be achieved by RFID printers, such as iDPRT iX4R UHF RFID Printer.

When it comes to printing and encoding flexible RFID tags, several crucial considerations must be taken into account:

1. Material Compatibility

Due to the distinct nature of flexible RFID tags compared to traditional rigid RFID tags, it’s essential to ensure that the chosen printer and printing materials are compatible with the characteristics of flexible tags. This may involve using specialized thermal transfer RFID printer ribbons tailored for them.

2. Adjusting Printing Pressure

Flexible RFID tags can be more delicate than their rigid counterparts, so it’s imperative to adjust the printing head’s pressure during the printing process to prevent any damage to the tag’s chip or antenna.

3. Alignment and Positioning

Precise alignment within the RFID tag printer is critical to prevent any printing deviations. Flexible tags may require more precise alignment control to ensure accurate printing.

4. Data Verification

After encoding, it’s essential to conduct data reading tests to validate the successful encoding process. The reading performance of flexible tags may differ from that of rigid tags, and verification is necessary.

5. Environmental Factors

Flexible tags may exhibit heightened sensitivity to environmental conditions such as humidity and temperature. Ensuring that the printing and encoding environment is conducive to these conditions is vital.

Advanced ’Dynamic Encoding’ Technology by the iDPRT iX4R Industrial RFID Barcode Printer

We highly recommend the iDPRT iX4R 4-inch RFID printer as the ideal choice for printing flexible anti-metal tags and RFID labels. This heavy-duty RFID label printer boasts exceptional precision and features an accurate printhead pressure adjustment mechanism.

When paired with its compatible enhanced hybrid carbon ribbon, it can clearly print a variety of texts, characters, logos, barcodes, and QR codes on flexible RFID labels.

For RFID tag encoding, the iDPRT iX4R utilizes advanced ’dynamic encoding’ technology. Here’s how it works:

1. The iX4R RFID barcode printer begins by printing the label while simultaneously sending encoding commands to the inlay.

2. It continuously monitors the signal strength emitted from the inlay.

3. When the iX4R detects the strongest signal, it pauses printing to focus on encoding the inlay at that precise location.

4. After the inlay is successfully encoded, this RFID tag printing machine resumes and completes the rest of the label.

This innovative process guarantees precise data encoding on the inlay, even when its position is not perfectly aligned with the printer’s antenna. This capability proves particularly advantageous in situations where the inlay is affixed to objects in motion, such as cartons or pallets.

Moreover, this industrial RFID printer features an antenna located at the paper exit point. Following the printing of RFID labels, it conducts a supplementary read verification, solidifying the dependability of the encoded data. This step is crucial in confirming the accuracy of the information on the RFID tags, providing an additional layer of verification for quality assurance.

The iDPRT iX4R RFID printer, a powerhouse of versatility, can handle an extensive range of tags, including flexible RFID tags, soft RFID tags, flexible anti-metal tags, UHF RFID labels, RFID asset tags, RFID clothing tags, and RFID medical device tags.

Ideal for tracking goods in a warehouse, managing retail inventory, or overseeing medical supplies, the iDPRT iX4R delivers the reliability and precision essential for modern RFID applications. Interested in enhancing your business with RFID technology? Contact us at iDPRT for RFID printer prices and tailored, efficient RFID label printing solutions.