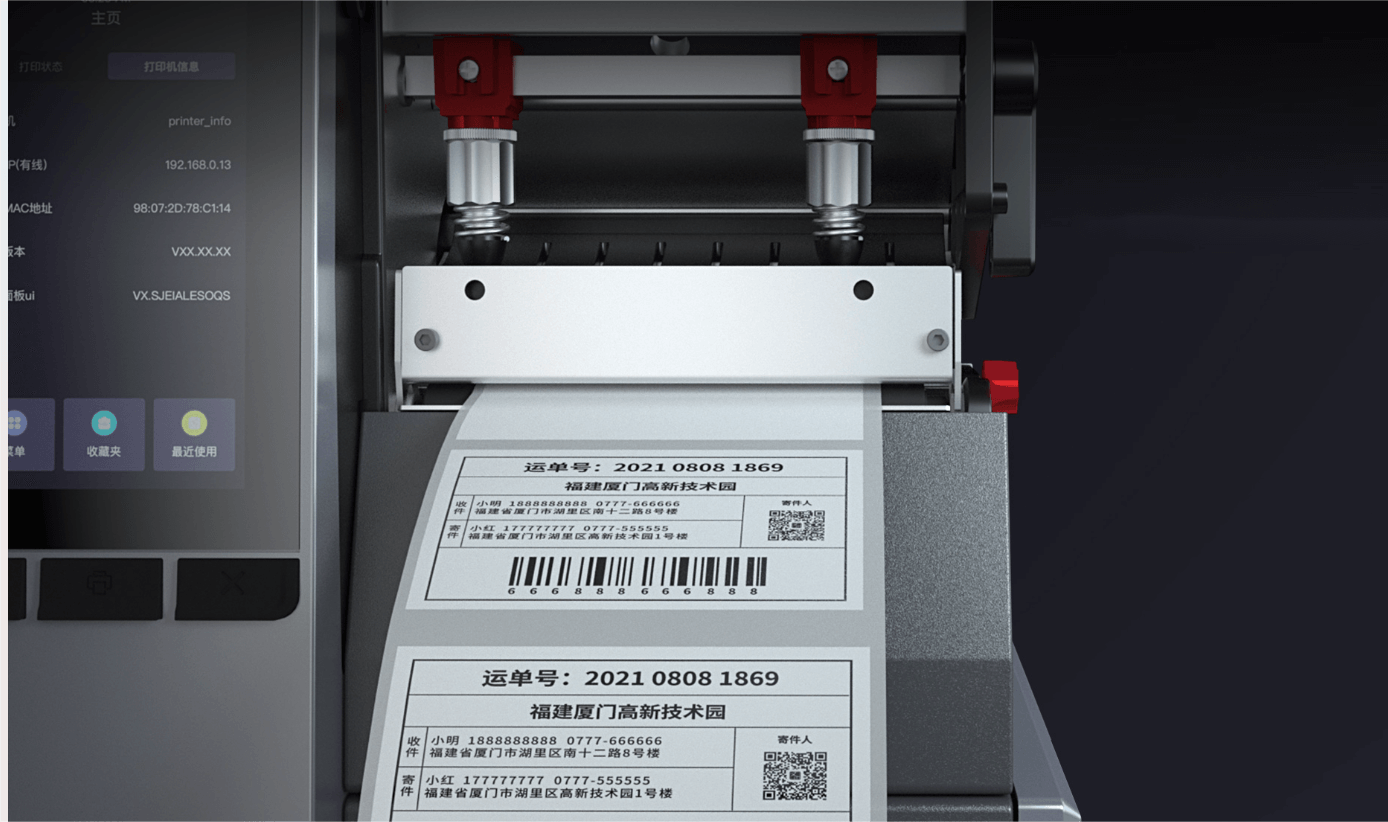

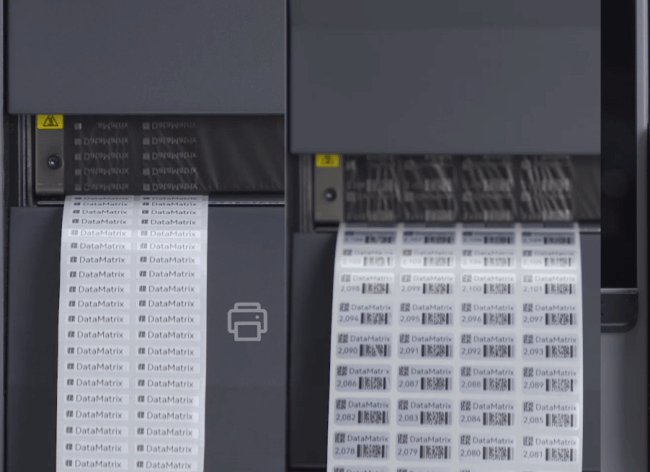

If you’re printing in hot warehouses, cold-chain logistics, or dusty production floors, your printer needs to handle the heat (or chill).

Industrial models like the iX4P are built with rugged housing and wide temperature operating ranges, ensuring consistent performance in challenging environments.

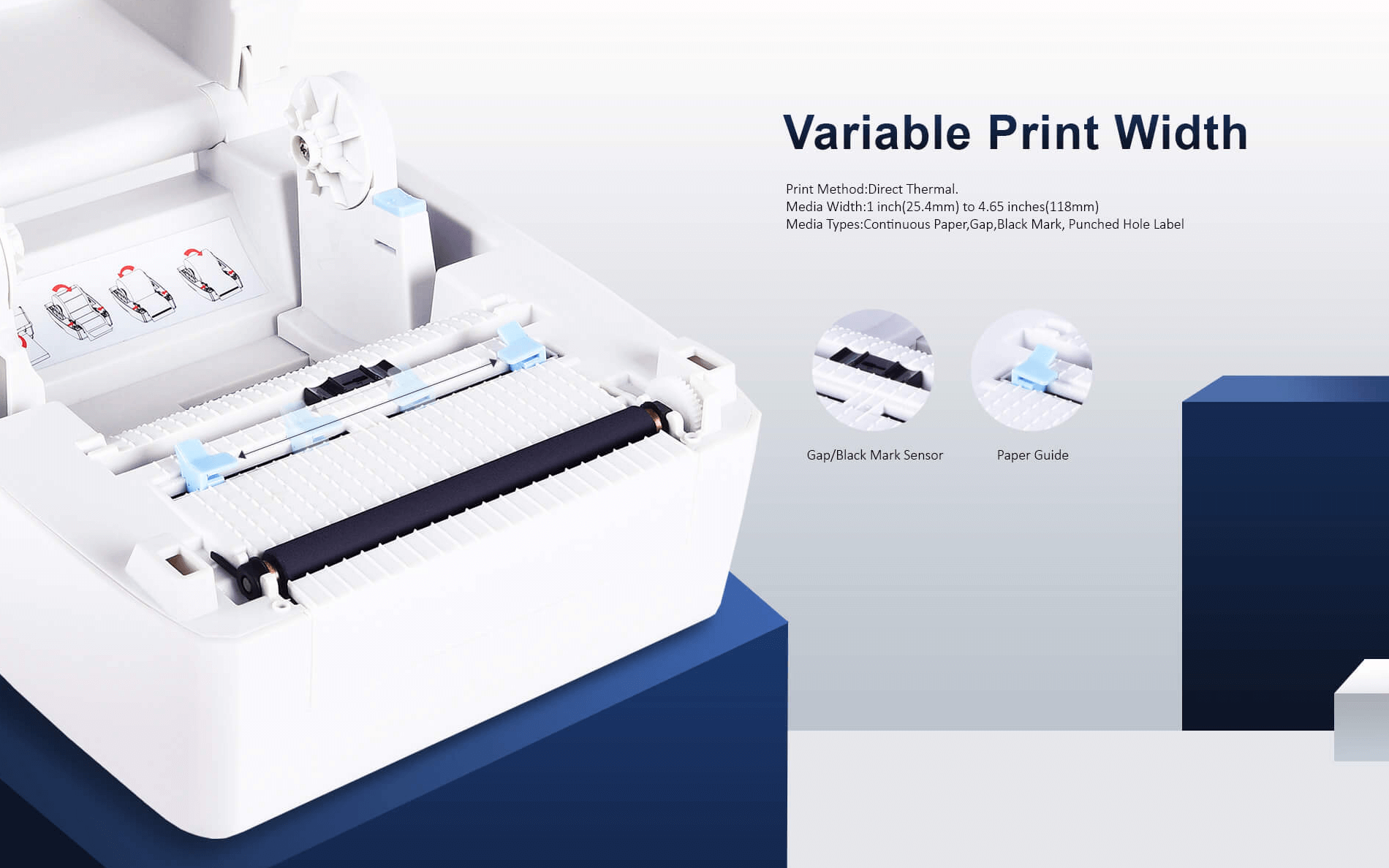

Is your printer living in a climate-controlled office, or braving the warehouse dust and humidity? Look for IP ratings (dust/water protection) and operating temp ranges.

Take the iDPRT iX4P, for example. This high performance industrial printer features a rugged industrial-grade shell and built-in sensors that automatically adjust for temperature and humidity changes. Designed to operate reliably from –10°C to 40°C, it's built for round-the-clock performance in tough conditions. Whether in a logistics hub or a high-volume production line, it delivers the kind of durability that demanding workflows depend on.