Why Proper Barcode Printer Setup and Maintenance Matters

A misaligned printhead, dust on the rollers, or incorrect label calibration can quickly lead to poor barcode readability. This doesn't just waste labels—it disrupts workflows and causes delays at checkout or in the warehouse. Regular maintenance, proper calibration, and correct setup help minimize downtime, extend printer lifespan, and ensure every scan counts.

How to Set Up a Barcode Printer?

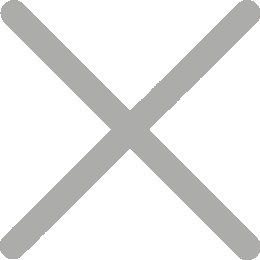

Unboxing and Placement

Start by unpacking the printer carefully. Choose a stable, dust-free surface near power and data connections. Avoid placing the printer in high-humidity or direct sunlight environments.

Connecting to Power and Network

Use the manufacturer-supplied power adapter and connect the printer to your system via USB, Ethernet, or Wi-Fi, depending on your model. For network printers, assign a static IP to avoid future connection issues.

Installing Drivers and Software

Download the latest drivers and utility software from the manufacturer's website. This ensures compatibility with your OS and unlocks all printer features. For Windows users, make sure the printer is recognized in "Devices and Printers."

Loading Labels and Ribbon

Open the media compartment and carefully load the label roll and ribbon (for thermal transfer printers). Make sure the labels are properly aligned and feed smoothly through the sensors. Close the cover and check for media detection.

Set Default Printer Preferences

Before your first print job, configure default settings on the computer to avoid label misalignment or print errors. Key settings include:

-

Media Type (Gap, Black Mark, Continuous): Match the setting to your label type to ensure proper label detection and avoid skipping or offset printing.

-

Label Size and Gap: In the driver or label editing software, input the exact width and height (usually in mm). For die-cut labels, specify the gap between each label.

-

Print Speed: Adjust based on content complexity. Medium speed (e.g., 4 ips) is suitable for text and barcodes; reduce speed for graphics or high-density barcodes to improve clarity.

-

Print Density: Start with the default setting and fine-tune as needed. If barcodes appear faint, increase the darkness level gradually.

Barcode Printer Calibration

1. Why Calibration Is Important

Barcode printers—whether direct thermal or thermal transfer—rely on accurate media detection to print correctly.

Since label sizes and formats vary widely, calibration helps the printer’s sensors accurately detect the start position and length of each label—preventing misalignment or skipping.

2. Barcode Printer Sensor Types and How They Work

Gap Sensor (Transmissive Sensor)

Used with die-cut labels, this sensor detects the gap between each label by measuring light passing through the liner. It’s common in both direct thermal and thermal transfer printers using standard adhesive labels.

Black Mark Sensor (Reflective Sensor)

Detects black marks or notches printed on the back of the label. Suitable for tag stock or continuous media without physical gaps—commonly used in apparel, retail, and logistics.

Recommended Reading: Understanding Black Mark Detection in Label Printers

Notch or Hole Detection

Some black mark sensors can also detect cutouts or perforations on the backing. This functions similarly to black marks for identifying the start of each label.

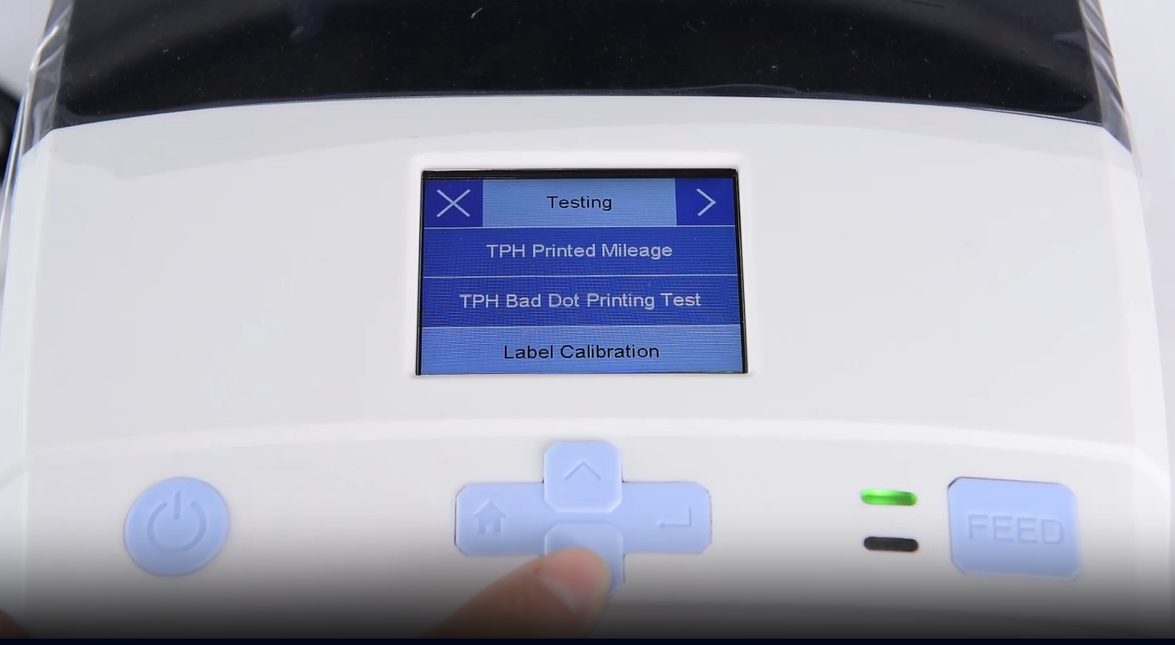

3. How to Calibrate a Barcode Printer?

Calibration can be performed automatically via the printer's interface or manually with software. Always consult your manual.

General Auto-Calibration Steps

- Power off the printer.

- Press and hold the "Feed" or "Pause" button (varies by brand).

- Power on the printer while holding the button.

- The printer will feed several labels to detect label parameters. Release the button to complete calibration.

For finer adjustments—such as label start position, length, or sensor sensitivity—use the driver or label software for manual calibration. This is especially useful for non-standard or specialty media.

If you notice label misalignment or content shift during printing, troubleshoot by checking the following:

- Ensure the software label size matches your physical labels.

- Confirm the correct media type (Gap, Black Mark, Continuous) is selected in the driver.

- Re-run auto calibration if labels continue to shift.

- If the issue persists, the sensor may be dirty or worn out—clean it or contact technical support.

4. When to Recalibrate Your Barcode Printer

In addition, you should recalibrate your barcode printer when:

General Auto-Calibration Steps

- Changing label size or type

- Switching between label and tag media

- After cleaning the sensors

- If misalignment, skipping, or offset printing occurs

Barcode Printer Maintenance and Cleaning Tips

1. Tools You Need

- Isopropyl alcohol (90% or higher)

- Lint-free cloth or cleaning swabs

- Cleaning cards (for thermal printers)

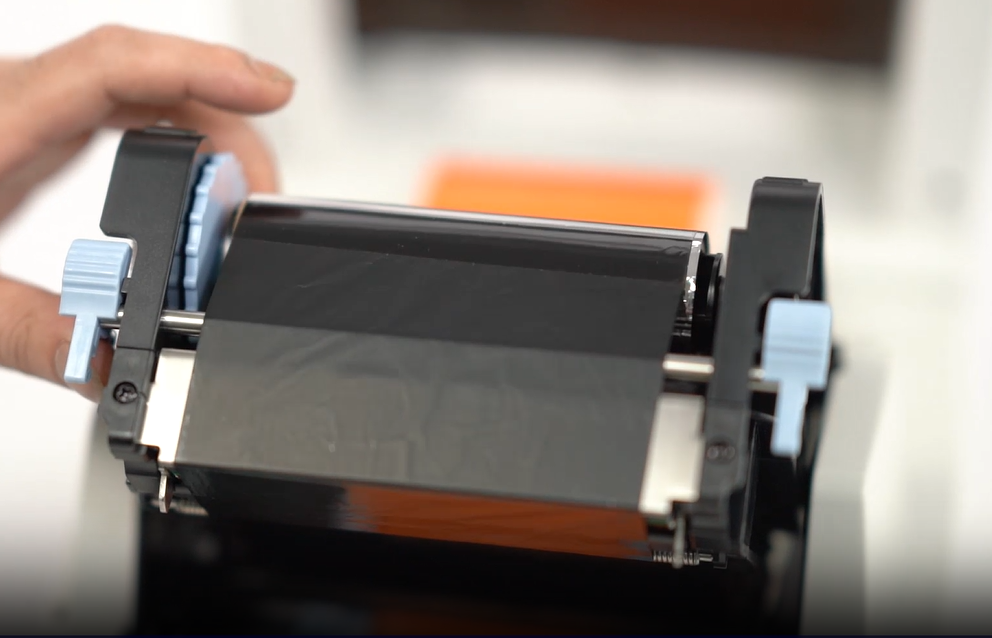

2. Cleaning the Printhead & Roller

- Turn off the printer and unplug it.

- Open the printhead assembly.

- Use a lint-free cloth lightly moistened with isopropyl alcohol and gently wipe the printhead to remove any residue.

- Let it dry completely before closing the cover.

3. Cleaning the Platen Roller

Remove dust and adhesive buildup from the roller using a cleaning card or alcohol-dampened cloth. Rotate the roller manually to clean the entire surface.

4. Sensor and Interior Maintenance

Use dry air or a soft brush to remove label dust from sensors and internal compartments. Avoid blowing dust deeper into the printer.

5. Maintenance Schedule

Common Barcode Printer Issues and Fixes

Faded or Incomplete Prints

Cause: Dirty printhead, incorrect heat settings, or low-quality labels.

Fix: Clean the printhead, increase heat via software, and use recommended media.

Label Skipping or Misalignment

Cause: Sensor miscalibration or wrong label settings.

Fix: Recalibrate the printer and verify label size/type in driver settings.

Wrinkled Ribbon or Smudging

Cause: Improper ribbon loading or platen roller issues.

Fix: Reinstall the ribbon with proper tension. Clean or replace the roller if needed.

Keep Your Printer Ready to Perform

Barcode printer maintenance doesn’t have to be complicated. With the right setup and regular care, your printer will deliver sharp, scannable labels every time. Follow these steps to reduce errors, extend equipment life, and keep your operations running smoothly.