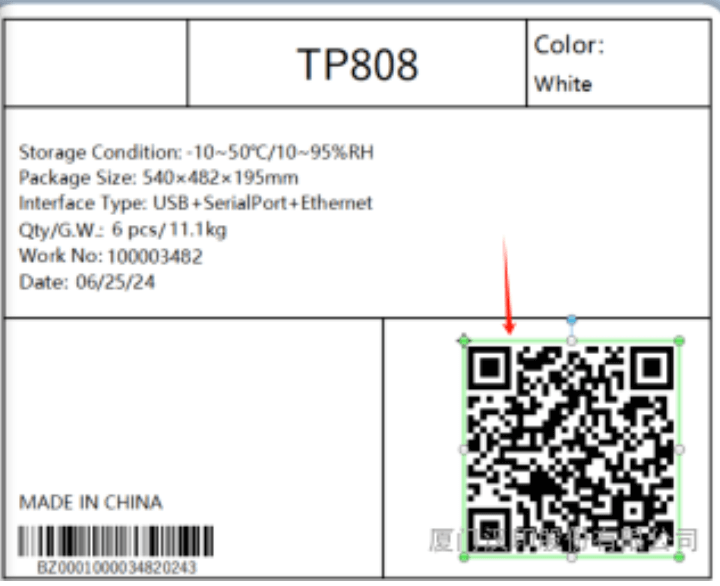

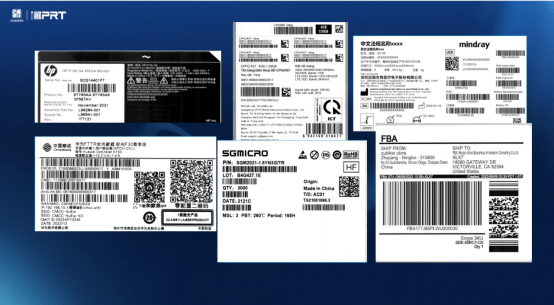

iDPRT barcode printers are stable and durable, with print resolutions up to 600 dpi. They work with both direct thermal and thermal transfer printing. These printers create sharp, easy-to-scan double barcodes, including GS1, ITF-14, QR Codes, and Data Matrix, which are widely used in logistics, fresh food, retail, and healthcare.

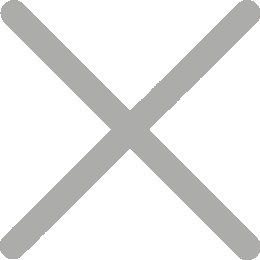

With the free BarTender software, you can quickly design and manage dual barcode labels. iDPRT’s industrial thermal printers also connect smoothly to logistics platforms, production lines, and enterprise systems, delivering reliable performance even in high-volume environments.