In today's apparel retail, the core of competition lies in inventory visibility and precise management. Knowing exactly what you have and where it is powers every decision, from stocking shelves to preventing lost sales. A growing number of fashion and footwear brands are adopting RFID apparel solutions to meet modern retail demands: fast and accurate inventory updates, real-time retail visibility, and full product traceability.

RFID Apparel Technology in the Fashion Industry

RFID, short for Radio Frequency Identification, works a bit like giving every item its own digital voice. It uses radio waves—no scanning, no touching—to share data between a small tag and a reader.

☞ Recommended reading: How Does RFID Work

In apparel production and distribution, garments embedded with RFID tags can be instantly identified in bulk by handheld RFID readers or fixed tunnel systems. This enables real-time inventory updates from factory to storefront.

For example, Uniqlo has deployed an RFID inventory system globally. The brand can monitor the movement and status of each item across production, logistics, and retail, achieving full end-to-end visibility from factory to sales floor.

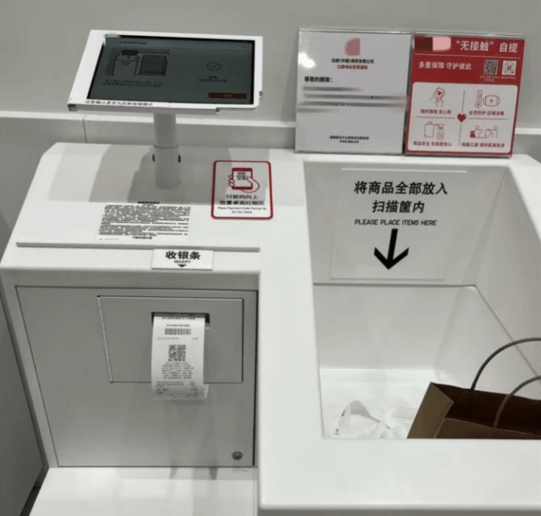

In stores, customers can use RFID self-checkout systems to pay instantly without scanning each item, greatly reducing wait times.

This intelligent experience not only enhances inventory transparency but also boosts customer satisfaction and store operational efficiency.

Types and Advantages of RFID Apparel Tags

Most fashion brands use UHF (Ultra High Frequency) RFID garment tags, offering long read distances and bulk identification. Common types include:

RFID Hang tags:

The retail standard for fast, accurate stock counts. Attached via a plastic fastener, these tags combine visible branding and pricing with a unique item-level identity. Ideal for in-store operations and seamless point-of-sale.

RFID Fabric & Taffeta Tag

Sewn directly into a garment's seam like a traditional care label. Endure laundering and dry-cleaning. Durable and washable, perfect for long-term tracking.

Compared with traditional barcodes, the benefits of RFID apparel tags are striking.

- Bulk reading — hundreds of items identified in seconds

- No line-of-sight requirement — readable even inside boxes or stacks or in motion

- Rewritable and data-rich — Each tag carries a unique ID that can be updated with more dynamic, flexible data.

- Durable, resistant to wear, dirt, and moisture — longer lifespan

That’s why an increasing number of fashion and footwear brands are adopting smart RFID solutions to power intelligent apparel management.

How the RFID Apparel System Works

A complete RFID apparel tracking and management system typically includes: RFID printers, RFID tags, handheld readers, RFID gates and tunnels, and management software, and network infrastructure.

Together, these components form an automated identification and tracking system spanning production, warehousing, and retail—serving as the technological backbone of smart inventory management.

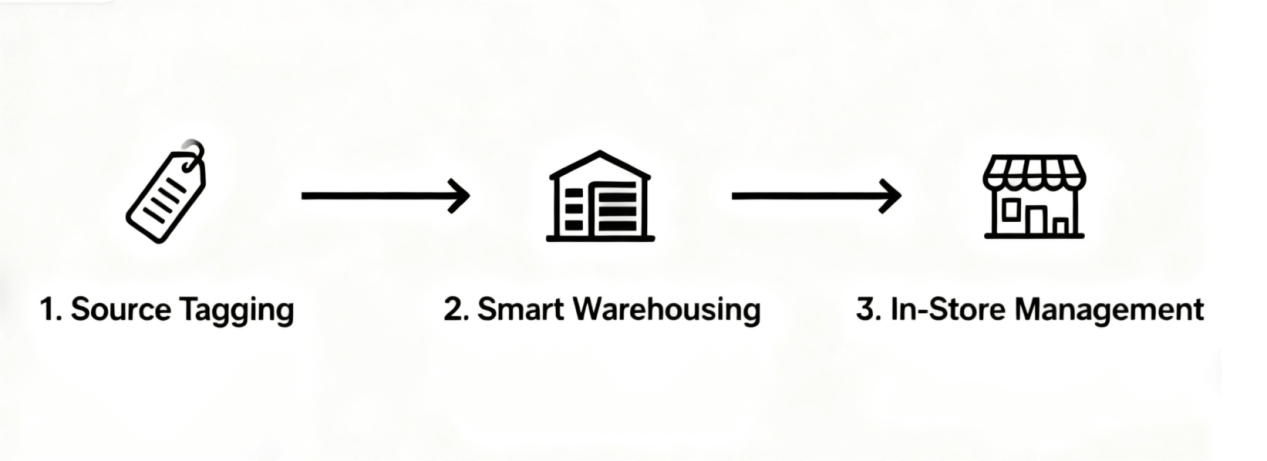

The Workflow

Source Tagging

At the manufacturing site, each garment is labeled with an RFID tag with embedded inlay.

Factories typically use industrial RFID printers to print and encode these RFID apparel tags. The tag stores a unique EPC code tied to the product's SKU, size, and color. Finished cartons or pallets often use both barcodes + RFID hybrid labeling.

Smart Warehousing

When goods arrive at the distribution center, RFID gates or handheld readers can identify entire cartons without opening boxes or aligning tags.

The RFID inventory system automatically verifies inbound and outbound data and triggers instant alerts for any discrepancies—greatly enhancing warehouse efficiency and data accuracy.

In-Store Management

Staff use portable RFID handheld readers for rapid stock counts and shelf replenishment.

Garments and shoes with RFID tags also support self-checkout, while enhancing loss prevention and traceability throughout the store.

By connecting every stage—from source tagging to smart inventory management—RFID technology helps apparel companies stay agile, compliant, and ahead of the curve.

Proven Benefits of RFID Apparel Solutions

When fully deployed across manufacturing, warehousing, and retail, RFID systems deliver measurable performance improvements.

According to data from several large apparel manufacturers and chain retailers, adopting RFID apparel solutions has led to dramatic gains in both efficiency and accuracy across production, logistics, and retail operations

Receiving and shipping verification:

Using next-generation RFID tunnel systems, a full carton can be scanned and verified in just 10 seconds—6× faster than manual weighing or barcode scanning.

Cycle counting

With an RFID apparel management system, staff can complete a full shelf scan in 3–5 seconds without removing items, reaching 150 items per minute—a 15× efficiency boost.

Shipment recheck

Manual carton scanning once took 4 minutes; now, RFID completes the task in 10 seconds, improving efficiency 24×.

Inventory accuracy

Increased from a traditional average of around 63% to 95–99%, ensuring near-perfect visibility across all stock locations.

From production lines to the sales floor, RFID apparel systems are transforming how fashion brands operate—driving higher efficiency, accuracy, and end-to-end transparency.

RFID Apparel Printing Solutions for Apparel Tags

Printing and encoding RFID apparel tags are critical to ensuring data accuracy and product traceability across every stage of apparel production and retail.

With professional label design software, iDPRT UHF RFID printers print clear, detailed information—such as size, SKU, and barcode—on apparel RFID hang tags and fabric labels, while simultaneously encoding digital data into each chip for real-time synchronization.

To guarantee reliability, each encoded tag is automatically verified. If an error or defective chip is detected, the system marks or rejects the faulty label to prevent invalid tags from entering the production line.

Every print, every code, every label stays in sync.

Best RFID Printers for Apparel Tags:

- Resolution: 203dpi,300dpi

- Print method: Direct Thermal and Transfer Thermal

- Max. print speed: 8ips @ 203dpi, 6ips @ 300dpi

- Max. print width: 4.25"(108mm) @ 203dpi, 4.17" (106mm) @ 300dpi

- Memory: 256 MB Flash / 128 MB RAM

iDPRT iT4R Series: Ideal for on-demand or replacement tag printing in stores and small production runs. Compact and easy to use, perfect for quick hangtag reprints or localized tagging needs.

- Resolution: 203dpi,300dpi

- Print method: Direct Thermal and Transfer Thermal

- Max. print speed: 14ips @ 203dpi, 8ips @ 300dpi, 4ips @ 600dpi

- Max. print width: 4.1"(104mm) @ 203dpi, 4.17"(106mm) @ 300dpi and 600dpi

- Memory: 256 MB Flash / 512 MB RAM

iDPRT iX4R Series: A high-performance RFID solution for large-scale manufacturing. Handles washable fabric & taffeta tags, and high-quality paper hangtags with outstanding precision and speed.

By integrating iDPRT RFID printing solutions, apparel brands can unify data flow across production, warehousing, and retail—achieving faster printing, fewer labeling errors, and complete RFID apparel tag traceability from factory to store.

Ready to make your apparel supply chain smarter?

Boost efficiency, accuracy, and visibility with iDPRT RFID printing solutions.

RFID Apparel & Clothing Tags FAQ

Q1: What does RFID mean on clothes?

It means the clothing has a tiny RFID tag—usually in the label or hangtag—used for inventory tracking and product verification.

Q2: Are RFID chips in clothing safe for consumers?

Yes. RFID chips emit very low radio signals and contain no power source. They are completely passive and harmless for daily wear.

Q3: Can RFID tags on clothes be tracked?

No. RFID tags can only be read at short range by store or warehouse readers. They can't be tracked remotely or via GPS.

Q4: Can RFID read through clothes?

Yes. UHF RFID signals pass through most fabrics, allowing quick bulk scans even when items are boxed or folded.

Q5: Can RFID clothing tags survive washing or ironing?

Yes. Washable RFID tags are made for such use and stay functional after many wash or press cycles.

Q6: What is the read range of RFID apparel tags?

Typical range varies between 2 and 8 meters, depending on tag size, fabric material, and reader antenna design.

Q7: Can RFID and barcodes coexist?

Absolutely. Many companies print both on the same label — barcodes for manual backup, RFID clothing tags for automated processing.