Quick Guide: How to Serialize Barcode Labels

In today’s manufacturing and logistics, product traceability is a must. Serialized barcodes provide the item-level tracking needed for complete inventory visibility and robust quality control. This is how companies track individual items through their entire lifecycle—from production to the end consumer.

But what exactly are serial barcodes? How are they different from standard barcodes? And most importantly—how can you generate them correctly and efficiently? Read on to find out everything you need to know.

What Is a Serialized Barcode?

A Serialized barcode is a unique identifier encoded into a barcode symbology that allows each product to carry a distinct, trackable number. Unlike batch codes or static barcodes, a serial number on a barcode changes incrementally (or dynamically) for each unit.

This process is called barcode serialization. It's commonly done using variable data printing and works with many barcode formats, such as Code 128, Code 39, QR codes, and Data Matrix codes.

For example:

Product A, unit 1 → Serial No. 000001

Product A, unit 2 → Serial No. 000002

... and so on

Of course, serial numbers don't always have to be sequential—they can also be randomized. The key takeaway is that each product is now traceable individually, which is critical in regulated industries, high-value manufacturing, and warranty systems.

How to Generate Serialized Barcodes

Creating Serial number barcodes requires specialized barcode design software. One of the most widely used tools in the industry is BarTender, developed by Seagull Scientific.

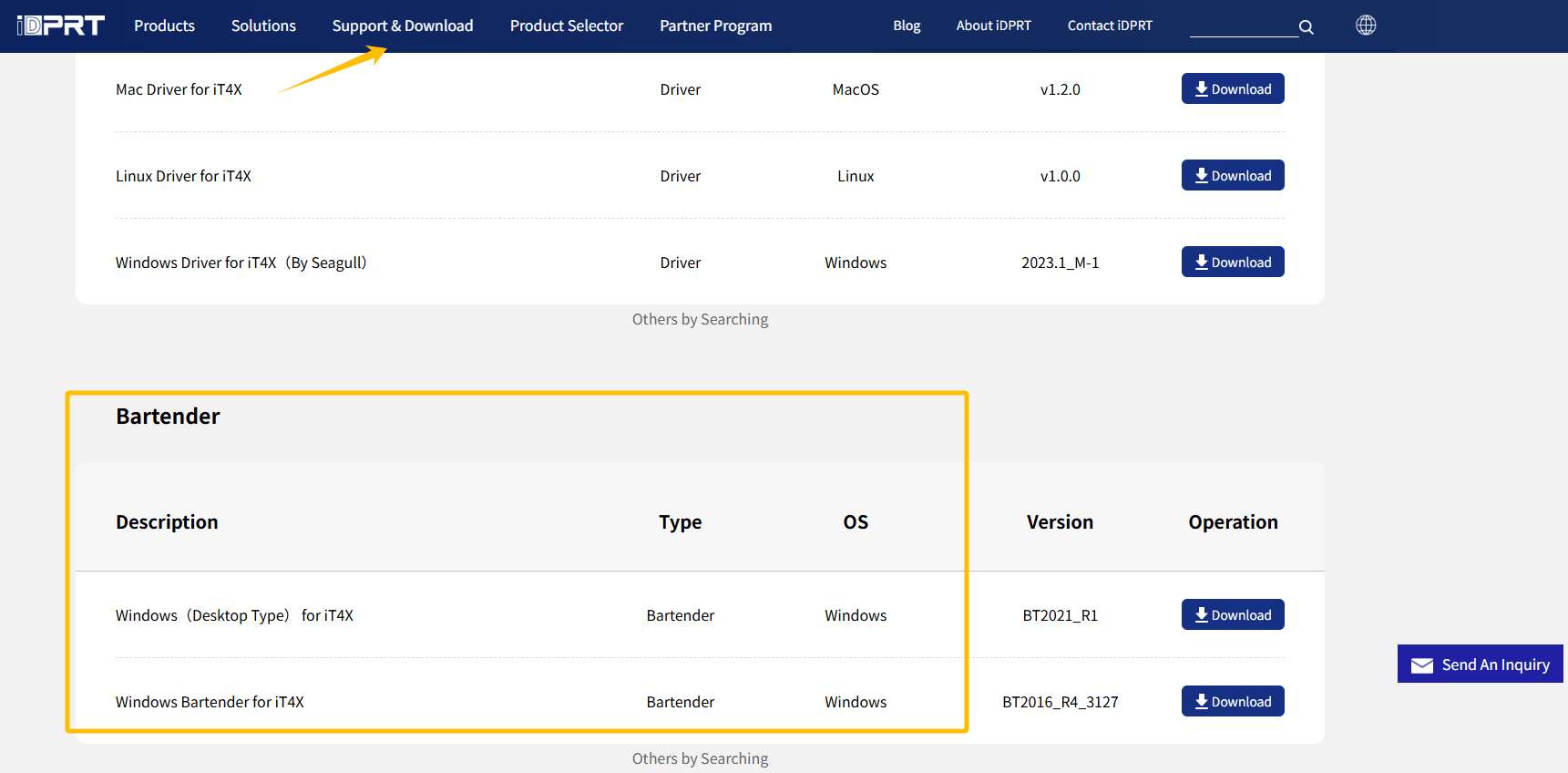

Many leading barcode printer brands—including IDPRT—offer full compatibility with BarTender. Users can easily download the appropriate BarTender version from IDPRT's official website and follow the step-by-step guide to activate and begin using it for free.

BarTender makes it easy to generate various serialized barcode labels tailored to real business needs. Common use cases include:

- Serialized labels (e.g., 00001, 00002, 00003…)

- Batch IDs and packaging codes

- Unique Product Identifiers (UIDs)

- Automatically incrementing label numbers based on order quantity

In BarTender, these requirements are generally fulfilled using the Counter feature in combination with Variable Fields.

Simply insert a barcode or text field into your label design interface, assign it a “serialized variable” as the data source, and configure parameters such as starting value, increment step, number formatting (prefixes, leading zeros), and reset rules.

Advanced Serialization Logic

For more advanced needs, BarTender also supports seamless database integration, enabling complex barcode and QR code serialization logic, such as:

- Shared serial ranges across multiple SKUs

- Date-based serial rules

- Real-time logging of serial numbers to an external database

These capabilities provide strong support for precise label serial number management and end-to-end traceability in industries like manufacturing, logistics, and warehousing.

Benefits of Using Serialized Barcodes

Why combine serial numbers and barcodes? Here are the real-world benefits:

Compliance with Regulations

Many industries like pharmaceuticals, medical devices, food, and electronics require strict traceability. Labels with serial numbers are a practical and often mandated solution.

Counterfeit Prevention

A unique serial number barcode acts as a digital fingerprint for each product, making counterfeiting significantly more difficult.

Faster Product Recalls

If a product issue arises, barcode serial number data enables precise identification and isolation of affected units—without disrupting entire batches.

Accurate Inventory Control

Track individual items instead of relying on batch-level approximation, increasing accuracy and accountability.

Enhanced Consumer Trust

When a serial barcode links to an official verification platform, it builds transparency and trust with end users.

Because of these benefits, barcode and serial number tracking solutions are now a priority for businesses across industries—from factories and warehouses to retail shelves.

Choosing the Right Barcode Printer for Serialized Barcode Labels

To ensure consistent, high-quality output of serial number barcodes, it's essential to choose a barcode printer you can rely on.

IDPRT offers a comprehensive range of printers for demanding environments such as manufacturing, logistics, and healthcare—supporting everything from small-batch to large-scale serial barcode generation and label printing.

Recommended Models:

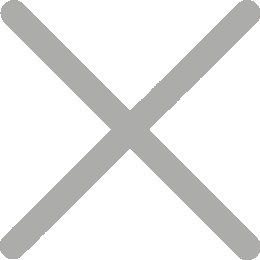

iX4P High-Volume Industrial Barcode Printer for Manufacturing

- Resolution:

- 203dpi,300dpi or 600dpi

- Printing method:

- Direct Thermal and Transfer Thermal

- Max. print speed:

- 14ips @ 203dpi, 8ips @ 300dpi, 4ips @ 600dpi

- Max. print width:

- 4.1" (104mm) @ 203dpi, 4.17" (106mm) @ 300dpi and 600dpi

- Memory:

- 256 MB Flash / 512 MB RAM

iK4-R600 – UDI Barcode Printer with Verifier

- Resolution:

- 203dpi, 300dpi or 600dpi

- Printing method:

- Direct thermal/Thermal transfer

- Max. print speed:

- 14ips @ 203dpi, 10ips @ 300dpi, 6ips @ 600dpi

- Max. print width:

- 4.1"(104mm) @ 203dpi, 4.17"(106mm) @300dpi and 600dpi

- Memory:

- 2 GB Flash / 512 MB RAM

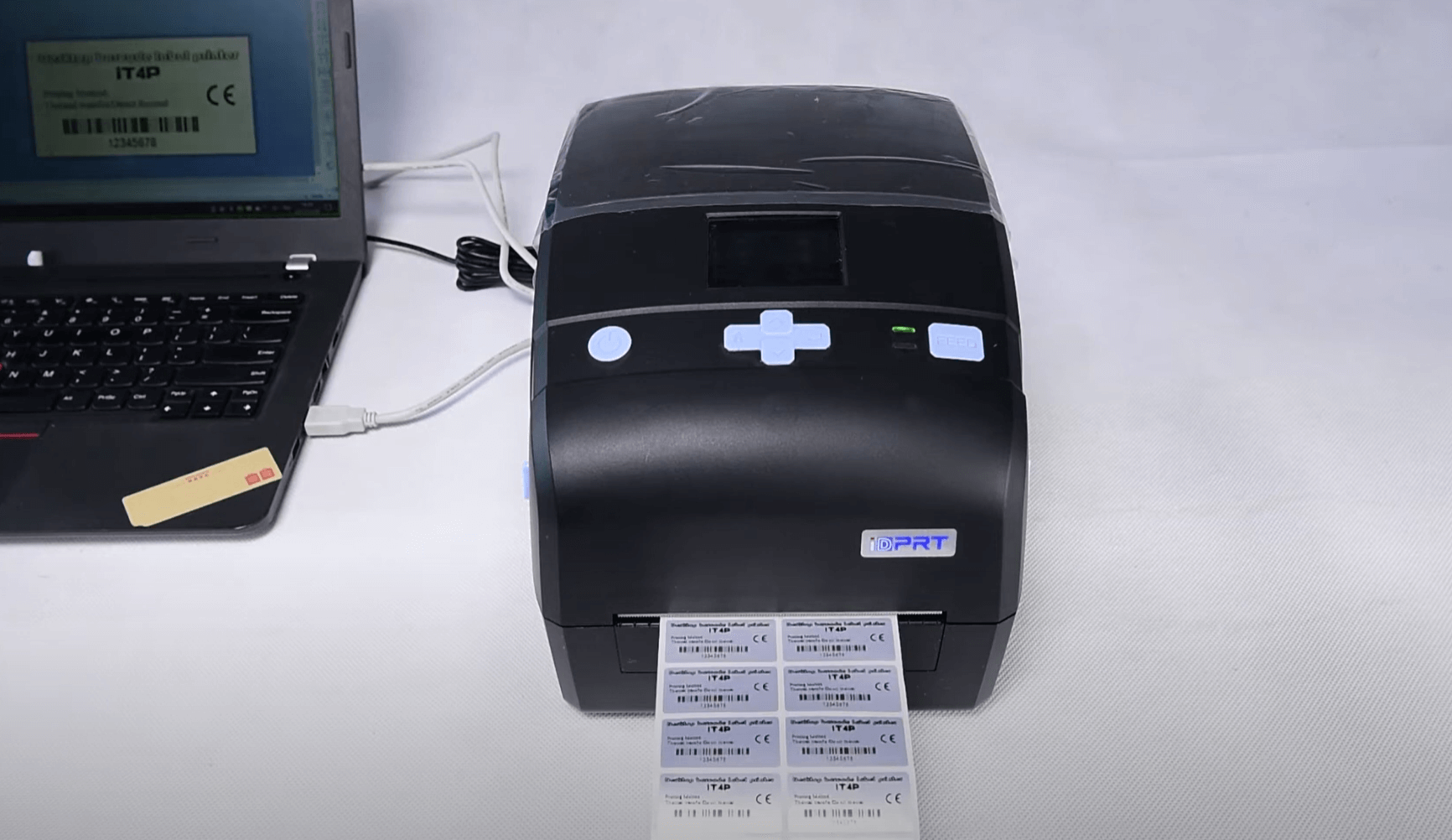

Product Demonstration Video

Need help selecting the right barcode serial printing solution for your workflow?

Our technical experts are here to provide prompt, tailored assistance to help you achieve seamless traceability. Get in touch today and streamline your labeling operations with our advanced serialization tools.

Smarter labeling. Stronger traceability

Find the Right Barcode Printer Fit for Your Workflow